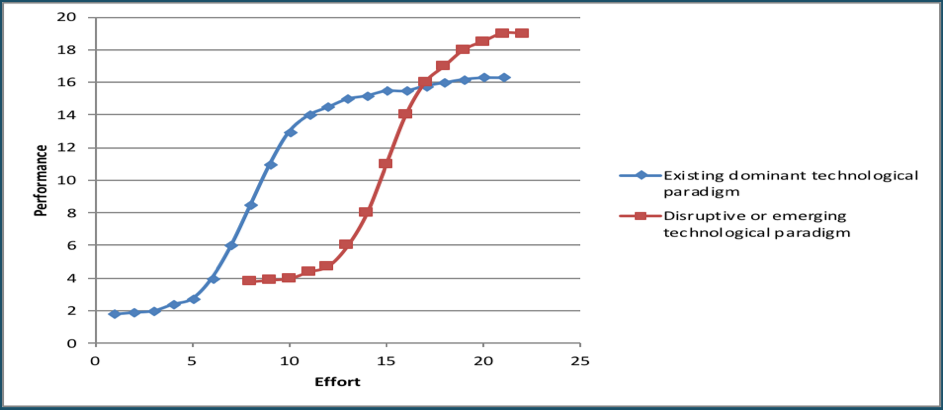

In the earlier research on technological evolution in the 1970-1995 period, attention was mainly paid to either a whole economy or a single sector or technological paradigm. It is broadly understood from this research that different industries and technologies evolve at different rates. This means that over time, some industries may be more important than others, or at least, some may be accelerating while others may be stagnant or declining. In recent research by Saviotti and Pyka (2013), the emergence of new technologies and industries (and the goods and services that they provide) is seen as offsetting the diminishing returns that are innate in the development of existing technologies. Nelson (2015) argues that this is a reason why absorption and further development of these technologies are necessary to maintain economic development.

In enabling technological evolution in countries, a whole range of actors play a part. Individuals and informal networks, to large and small firms all play a role. However, for the last century, most technological advancements have been supported by scientists, the academia and professional societies and a range of supporting meso organisations. In Europe, professional associations often play an important role in the deepening and dissemination of technological knowledge.

I want to come back to the meso organisations mentioned in the earlier paragraph. Meso organisations or functions are created in response to structural issues like market failures, sometimes government failures or persistent patterns of underperformance in the economy. These meso functions are critical in supporting economic actors to discover what is possible in a given economic context, to assist stakeholders to overcome coordination failures, and to provide critical public goods (such as scarce or expensive technological infrastructure, demonstration facilities, testing facilities, public research, and so on).

The meso functions enable a society, industry or even the public sector to discover and absorb new ideas, they enable learning by doing, they encourage the adaptation and dissemination of new knowledge or technologies, and they connect different stakeholders to overcome coordination and search failures. These meso functions are a critical ingredient in the local innovation system as they extend the technological capability of a given sector, industry, market or region in a country.

You would have noticed that I have not yet mentioned universities and public research efforts. This is simply because I have written about them so often as they form a critical part of the local innovation system. I sometimes even think that the higher education sector receives too much attention. Yet, education from basic schooling to higher education plays a critical role. For me, a university is an important meso organisation, and research centres, technology extension centres and laboratories that provides testing facilities are all important meso functions or maybe even meso organisations hosted by a larger organisation.

The importance of the higher education sector in the technological infrastructure varies for different parts of the economy. Nelson contends that scientific and technological research and teaching, especially the more applied fields, provide a base of knowledge that is accessible to all technically sophisticated individuals and firms working to advance technology in a field (Nelson, 2015). However, different fields also depend, to different extents, on scientific and formal research and technology support. Therefore, measuring journal articles and research outputs as a contribution to the national innovation system or as a proxy for technological capability will always paint only a partial picture. It really also depends on the pace of change and scientific advancement that is taking place in a region, a technological domain or an industry.

Furthermore, different industries depend, to different extents, on government support and incentives. In some fields public support is crucial, and in other cases, provides little incentive or value. In many cases innovations preceded science, and continued development is only possible due to the iteration between researchers and enterprises. Nelson continues that the kinds of firms that do most of the innovating differ – in some fields this tends to be large, established firms while in others it is smaller firms or new start-ups (Nelson, 2015).

Nelson draws an important conclusion that has really shaped my own thinking. Nelson states that there is no single set of policies that are applicable to all technologies and industries. What will be effective in some fields will not be in others. For instance, small business promotion in some sectors in one country could work, but it could be ineffective in another country.

In South Africa, with its very high coordination costs and high compliance costs, smaller enterprises in the manufacturing sector are at a huge disadvantage. The distance to sophisticated buyers and the challenges with exports compounds the difficulty for smaller enterprises to compete globally from the local base.

Nelson is also known for his writing on the importance of a wide range of social institutions, both formal (for example a cluster development organisation) and informal (the trust networks between members of the clusters). He refers to these social institutions as social technologies, and he argues that they co-evolve with physical technologies to enable economic development. These social institutions range from central banks to a diverse range of firms, but importantly include other forms of organisations such as scientific and technological societies, universities, government agencies and even capital markets. These institutions are the focus of the discipline of innovation systems.

Nelson emphasises that “that when a potentially new technology emerges, new institutions often are needed to develop it, and invest in and operate effectively the economic practices based on it”.

Nelson acknowledges it is not an easy task, as it is hard to predict which emerging fields of promising new technologies are going to be important in driving economic progress in the future, and which will have a modest impact. The policies to create or reform institutions need to be adaptive and flexible. Arthur (2009:186) confirms the view of Nelson and argues that “We cannot tell in advance which phenomena will be discovered and converted into the basis of new technologies. Nor can we predict which combinations will be created.”

That brings me back to my intent with this post. When we look at technological disruption and change, it is very easy to get caught up in the potential or risks of any given technology. But we must not take our eye of the informal and formal institutions, market systems, regulations and technological domain specific organisations that are needed to make a new technology viable. At the same time, we also have to figure out how to gracefully exit older technologies and how to either shut down or transform public organisations that once had a critical role in supporting those industries and technologies.

Again, I repeat, the so-called fourth industrial revolution is going to be more disruptive at the level of institutions and social arrangements than it will be disruptive for the enterprises that are competing at the technological frontier.

In South Africa, we have a triple-challenge.

1 – Our institutions change very slowly, and we have huge social tensions about how to allocate resources and wealth in the economy. Our local municipalities and local economic development activities are ineffective (with some exceptions in some of the larger metros). Yet, local authorities have hardly any influence over the quality and effectiveness of national meso programmes that are supposed to enable economic change.

2 – This is compounded by a largely uncompetitive economy with lots of market concentration. The regulatory burden in the economy keeps a lot of potential entrepreneurs employed in the corporate and the public sectors.

3 – Our discussions in South Africa about technological change, technological capability and the promotion of the innovation system is dominated by a linear logic of science leading to technology leading to innovation (the so-called STI approach). There is not enough attention being paid to the eco-system of organisations, technology extension agencies that can help enterprises master new technological domains, reduce coordination costs, the so-called Do, Use, Integrate (DUI) kind of innovation. On that point, we also have very few (if any) technological organisations tasked with transforming or upgrading whole sectors or regions in the country from a technological perspective. Everything is aimed at one enterprise at a time.

My research agenda:

This is what my research is about at the moment. I am working with a team from TIPS and the dti (South African Department of Trade and Industry) to strengthen the visibility of this technological meso network, while also strengthening the public sectors ability to spot technological disruptions and to be more pro-active.

Please sign up below if you want to stay informed of our progress as I will not be able to share all of our learning in the public space all the time.

Sources:

Arthur, W.B. 2009. The nature of technology : what it is and how it evolves. New York: Free Press.

Nelson, R.R. 2015. Understanding long-run economic development as an evolutionary process. Economia Politica,Vol. 32(1) pp. 11-29.

Saviotti, P.P. and Pyka, A. 2013. The co-evolution of innovation, demand and growth. Economics of Innovation & New Technology, Vol. 225 pp. 461-482.